Brandon Medical Carbon Reduction Plan

Commitment to achieving Net Zero

Brandon Medical Company Ltd is committed to achieving Net Zero emissions by 2045.

Pledge to Net Zero

Annual Report Back Form 2025

This form is part of the annual Pledge ~o Net Zero reporting back process.

Environmental Sustainability

Annual Report 2022

Brandon Medical is one of the only ASMS companies in the UK to join the Pledge to Net Zero (https://www.pledgetonetzero.org/) to establish science based targets for reducing greenhouse gas emissions. The Company has been selected as an exemplar of good practice to speak at Pledge to Net Zero, Medilink and Leeds City Region conferences to share best practices in real-world reductions.

We have a comprehensive Green Sustainability Plan, modelled on the NHS Trust Green plans, to align our actions with the needs of NHS Trusts.

Most ASMS products are imported by large international companies who manufacture components and final products in China where electricity is predominantly generated from coal and there are significant transport emissions. Brandon Medical manufacture ASMS products in Leeds from locally sourced materials, close to our main NHS customers. As a UK manufacturer, the business has concentrated on our Scope 1 and 2 emissions by reducing our use of hydrocarbon fuels and grid-supplied electricity. These are areas where we have the most control and ability to reduce real-world emissions. We have already exceeded our 2026 targets with 27% reductions from our base year of 2021. We are now working on our NHS Carbon Reduction Plans and Scope 3 emissions reporting.

Design phase (designing for sustainability)

We are continually designing new products with a target of 30% lower embedded emissions for each generation of products.

Material selection (use of recycled materials)

We are designing new products which are largely made using recycled polymers and aluminium. We source our materials from UK sources to ensure control and that suppliers are also using low-emission materials.

Manufacture

We manufacture close to NHS Clients in the UK. Brandon Medical has one of the most energy efficient factories in the North of England, highly insulated, with SMART building controls and on-site PV generation.

Packaging materials/packaging reduction,

We have eliminated all plastic load fill materials and replaced them with recycled cardboard. Packaging tape has been replaced by reinforced paper tape. Package sizes have been reduced, in some cases by 50%.

Transport and delivery

We do no source products from distant countries. All our products are made in the UK or a small number of suppliers in Germany and Switzerland. All products are delivered by road/sea (no air freight).

In use phase (energy and emissions)

Brandon Medical’s ASMS are all naturally low energy or passive in use. Our operating lights are some of the most energy efficient in the World. Our SMART operating theatre control products are designed to reduce the energy needed to run operating rooms.

End of life

Brandon products are fully re-cyclable. We offer a service to disassemble end of life products into their constituent materials at our factory in Leeds where we have waste re-processing steams for steel, aluminium, polymers, cardboard, oils and electrical waste.

Environmental Policy

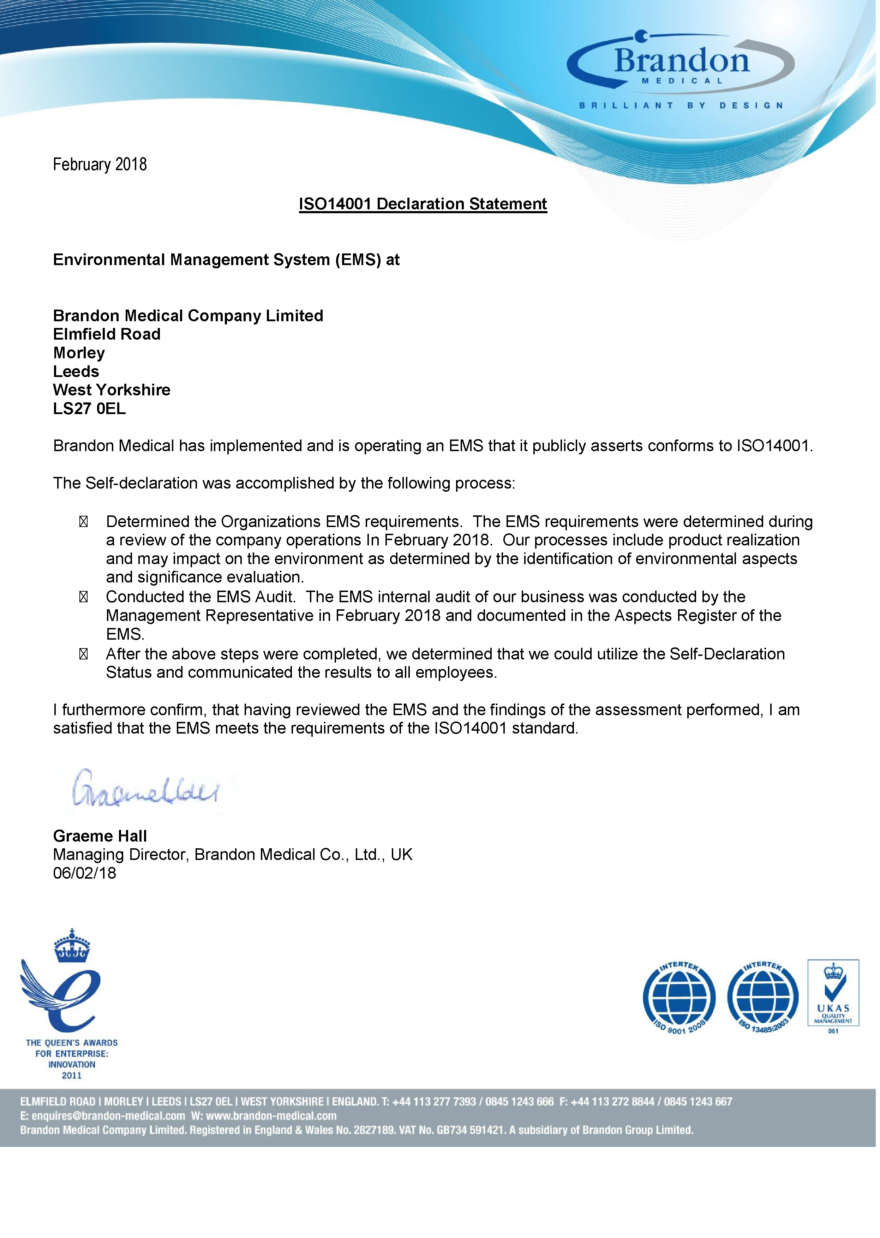

Brandon Medical has implemented and is operating an EMS that it publicly asserts conforms to ISO14001.

The Self-declaration was accomplished by the following process:

- Determined the Organizations EMS requirements. The EMS requirements were determined during a review of the company operations In February 2018. Our processes include product realization and may impact on the environment as determined by the identification of environmental aspects and significance evaluation.

- Conducted the EMS Audit. The EMS internal audit of our business was conducted by the Management Representative i February 2018 and documented it the Aspects Register of the EMS.

- After the above steps were completed, we determined that we could utilize the Self-Declaration Status and communicated the results to all employees.

I furthermore confirm, that having reviewed the EMS and the findings of the assessment performed, I am

satisfied that the EMS meets the requirements of the ISO14001 standard.

Brandon Medical Thought Leadership and Sustainability Journey Over a Decade: Sharing Our Know-How on Net Zero

Science, Technology, and Digital Transformation: Smart Hospital Innovations Driving Climate-Smart Healthcare

This article explores the intersection of science, technology, and digital transformation in healthcare, specifically focusing on smart hospital innovations and the adoption of digital health. It delves into the concept of climate-smart healthcare, which integrates sustainable and climate-conscious practices into healthcare services and infrastructure. By minimizing the negative environmental impact of the healthcare sector and enhancing overall sustainability, climate-smart healthcare aims to improve public health outcomes while reducing carbon emissions.

Brandon Medical’s Sustainability Journey Over a Decade: Sharing Our Know-How on Net Zero

In the pursuit of achieving Net Zero emissions, Brandon Medical offers a roadmap for SMEs. We advocate starting with clear motivations and offer a practical path to sustainability.