Ultraclean Ventilation Operating Theatre

Ultraclean Ventilation Operating Theatre Brandon Equipment Package (BEP)

Making the Invisible, Visible

Airborne Particle Monitoring and Control Systems Integration with Ventilation Canopies for Improved Infection Control and Higher Patient and Staff Safety

For many years, we have been able to achieve a high standard of hygiene in hospitals and operating theatres in the UK and elsewhere in Western Europe. However, intensifying cost pressures, the shortage of skilled surgical staff, and the increasing frequency of multidrug-resistant germs (MRSA) are now causing problems. Existing standards will therefore no longer be adequate in the future, and the risk of patients being exposed to infection during surgical operations will rise.

- Design and implement custom measures and renewed processes based on continuous airborne particle monitoring during surgical procedures, especially orthopaedic

- Visual indication of airborne particle load during operations for staff training and lasting behavioural changes in order to achieve higher patient and staff safety

- Cut energy costs and noise load through automatic, continuous airflow adjustments based on real-time monitoring of airborne particles.

Airborne particles are a critical factor that has a direct effect on the hygienic standards of the modern operating theatre and their significance is easy to explain: The fewer particles in the air, the fewer germs can be deposited on these particles, any particle above >0.5 microns are able to support viable bacteria which can lead to infection at the wound site.

The traditional measurement provided by a single annual test is simply not sufficient, once calibrated it is “assumed” that the performance of the UCV will not differ drastically over a 12-month term but there are many factors that can directly affect the performance.

Continuous, real-time monitoring – with visual indicators- allows for the implementation of improved procedures, risk minimisation, and cost efficiencies.

Expertise

Brandon Medical is a UK manufacturer and designer of world-leading technology solutions for operating theatres, critical care areas, and primary care institutions. For over 70 years, Brandon Medical has provided healthcare professionals with reliable, high-quality, and affordable medical equipment packages for operating theatres and critical care. Continuous investment in our products allows us to meet the ever-changing needs of our customers, the healthcare industry and the patients it serves.

We are acknowledged experts in medical lighting, medical power & control systems, medical video, and medical AV systems with unique expertise in providing integrated solutions.

We are one of the leading manufacturers of high tech medical lighting, and our equipment can be found in surgeries, clinics, and hospitals throughout the world supported by an extensive distributor network.

Equipment

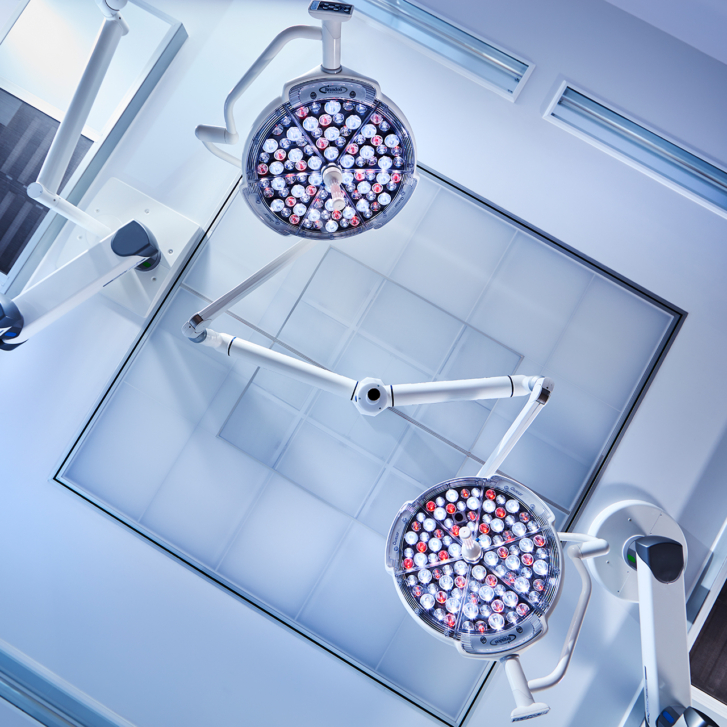

Our UK manufactured operating theatre lamps have near-perfect colour rendition, balanced arm systems for ease of movement, and use HD-LED technology which emits a brilliant cold light to reduce heat generation. We also have a range of mobile operating theatre lights. Specialist surgical and examination lighting systems are available, with unique features designed to suit the field.

In addition to healthcare and hospital lighting technology, we also manufacture operating theatre control panels and design solutions for medical AV systems, medical supply pendants, as well as isolated power systems and uninterruptible power systems.

Resources and technical memoranda for the facilities required for in-patient operating theatres in an acute general hospital.

Brandon Equipment Package(BEP) for the Ultraclean Ventilation Operating Theatre

Mediclean® Ultra Clean Ventilation

Quasar® eLite Operating Lights

Medipower™ iBEPU Intelligent Battery Emergency Power Units for Operating Lights

Atlas Pendants® - Operating Theatres

Medicontrol™ iTCP Intelligent Theatre Control Panels

Symposia View® Monitor Carrier

Symposia© Integrated Operating Theatre with Entoli HD

Symposia© Integrated Operating Theatre with Entoli 4K

Symposia® Surgical Video System

Medical Audio Video Components

Medipower™ Medical IT Power Supplies (formerly known as IPS

Medipower® UPS

Latest Article

Brandon Medical: Investing in the Future of Manufacturing

Brandon Medical is committed to nurturing the future of manufacturing by investing in apprenticeships, higher education partnerships, and community engagement. Recent successes, such as Tom Marchant's Apprentice of the Year award, highlight their dedication to developing skilled professionals and driving innovation in the industry.

Read more